OFFER & USE OF TRICKLE FILTERS IN AQUACULTURE

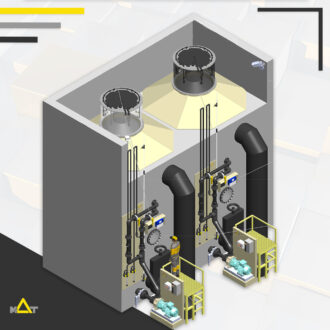

The Trickle Filters are fixed-bed, aerated, biotower filters designed to convert the toxic, nitrogen waste found in fish farming water to non-toxic byproducts. Trickle filter biotowers are filled with PE bioballs providing a surface area for micro-organisms to develop. This biological activity results to a gaseous exchange process restoring the levels of CO2 and O2 to viable levels. The biotower model range covers TAN removal rate from 10 gr TAN/day up to 1800 gr TAN/day and from 10kg up to 2600kg, of Max Biomass at 4% feeding ratio, per bio-tower.

Our biological filters, combined with other RAS equipment is the traditional solution for TAN removal in fresh and saline water facilities.

MAT-KULING Trickle Filters are applicable to any biologically charged water volume and it is commonly used to fresh and marine RAS farms and hatcheries.

OPERATION & ENGINEERING OF TRCIKLE FILTERS

The Trickle bio-tower Filters, receive pre-filtered biologically charged water which trickles through biomedia (PE bioballs). The media surface offers the layer onto which a biomass of microorganisms is thriving by removing the ammonia through chemical reactions. They are designed to maintain the conditions for maximum microorganism population growth and dead zone elimination. The Trickle filtration is the traditional solution for high TAN Load Removal, by maximizing the wastewater trickling surface, and by optimizing gas exchange.

ADVANTAGES OF TRICKLE FILTERS

- Improved Wet & Dry Filtration

- Advanced Filter Design

- High BOD Treatment Capacity

- Improved Gas Exchange Interface to Restore CO2 and O2 levels in the water

- Minimized Filter Clog

- No Need of Periodic Backwashing

- Resistive & Durable Structure

- Simplicity in Design & Ease in Operation & Maintenance