OFFER & USE OF GLASS FILTER MEDIA SYSTEMS IN AQUACULTURE

Pressurized Mechanical Filters are rapid, and pressurized multi layer filters which are filled in with Glass Filter Media instead of silica sand, for multiple advantages and advanced performance. Glass media offer many times more surface area than the sand media, is electrostatically charged to absorb organic substances and small particles. The developed filtration speed varies between 20-25m/h at a pressure rate of 2.5 bar. The specific filter configuration offers extra resistance to bio-fouling, to bio-coagulation and does not permit any unfiltered water to escape due to transient wormhole water channeling.

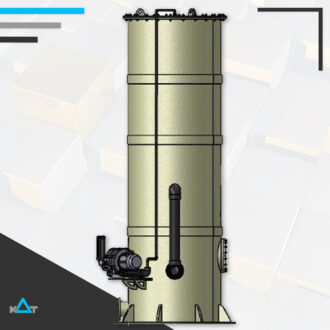

Our Pressurized Glass Filtration Media are specifically designed to provide backwash operation, by reversing the water delivery to flow from the lower to the higher media layers collecting and discharging the deposited particulate matter to the effluent waste line. Their vessels are fabricated either by steel, or vinylester coated FRP.

Glass Filter Media work with 50% less water flow compared to traditional sand filters. The media used allow long lasting usage.

Where Can Glass Filtration Media be used?

Glass media may be used for any pressurized vessel. MAT-KULING Pressurized Mechanical Glass Media Filters are specifically designed and fabricated pressurized vessels for fish hatcheries, fish farms and other aquaculture applications.

OPERATION & ENGINEERING

The wastewater is dispersed evenly over the Activated Glass Media by diffusers which are located on the upper part of the vessel. As the water permeates down through the media layers, the particulate material carried in the water is deposited to the Activated Glass Media. The GFM is manufactured from aluminosilicate glass, subjected to form a large nanostructure effective area. The metal oxide catalysts located on the media surface give a high redox potential making GFM media self-sterilizing, against undesirable microorganisms.

Advantages of Pressurized Glass Filtration Systems

- More than doubled performance over a conventional sand filtration system

- Higher effective filtration surface than sand

- Secures Biodynamic Stability

- Limits untreated water escape

- Substantially lower chlorine oxidation needs

- 50% lower backwash water rate

- GFM media do not require replacing

- GFM are a Self-Sterilizing Media

- No bacteria growth, thus no bio-fouling & no bio-coagulation